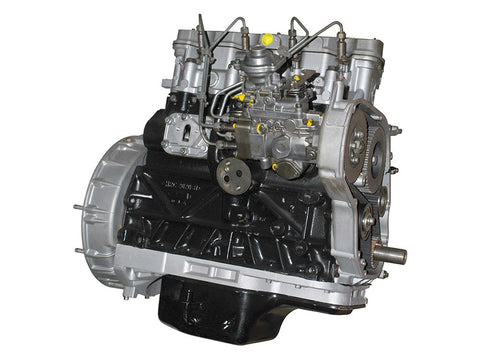

Defender 200Tdi Engine Parts

Engine parts and Ancillaries for your 200Tdi diesel Defender

The 200Tdi was one of the first mass-produced small-capacity direct-injection diesels, with the attendant improvements in power and efficiency that system brings. For production reasons, it had to be machined on the existing machinery, so used the same block and crankshaft as the existing 2.5-litre diesel engines. It also used many ancillary parts used on the older engines. An aluminium alloy cylinder head reduced weight and noise, a new Bosch injection system gave improved running characteristics and better starting performance. An intercooler boosted power and efficiency further. Lessons learnt from the Diesel Turbo were included, such as the fitment of an inertial separator in the breather system to remove oil before crankcase gases were returned to the air intake. The 200Tdi was fitted to the Defender in late 1990 - For this application the engine was slightly de-tuned and, whilst in the Discovery the 200Tdi used all-new components, packaging restraints in the Defender meant that the 200Tdi in this role shared many exterior parts (such as the timing belt system and case) with the Diesel Turbo. Most obviously the turbocharger was retained in the Diesel Turbo's high mounting position on top of the manifolds in the Defender, rather than being tucked under the manifolds in the original Discovery version.

It has established itself as a powerful and long-lived unit that with proper maintenance can exceed 300,000 miles of use. The engine's commonality with the older models makes it a popular choice for installation in older Land Rovers. This is done both in original form or with the turbo removed (when the engine becomes known as a 200Di) in order to keep the power/torque output within the limits of a Series Land Rover's gearbox and for greater ease of conversion. The turbocharged version may also be installed with or without the intercooler.